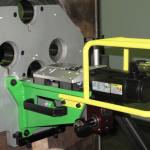

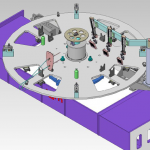

Special machines, automation and robotics equipment

CYBERMECA designs and manufactures effective means of production.

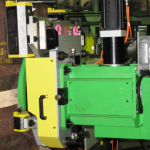

We design special machines for all major industrial sectors such as aerospace, automobile, defence, rail industry, etc.

Our modern and dedicated Research Department will ensure the success of your project.

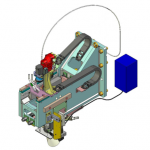

CYBERMECA is based in PERIGNY. This location includes :

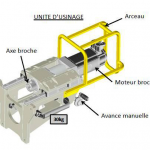

- The Mechanical research department (software used : Solidworks, Catia …)

- The Automation research department (CN NUM, Siemens, heidenhain control)

- The Hydraulics research department

- The assembly station for machines designed by the research departments

- A fully equiped machine shop

YOUR PROJECT

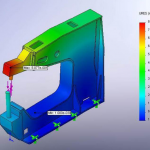

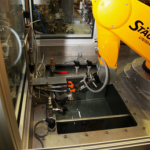

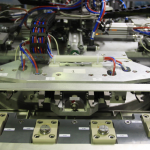

CYBERMECA research departments are able to carry out studies based on finite elements modeling, design and manufacture of power stations, numerical-control programming, automatons, robots and vision systems. CYBERMECA also develops HMI (Human Machine Interface) based on cutting-edge programming as well as wiring and pneumatic diagrams.

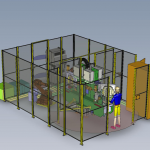

Because of customers’ specific requirements, CYBERMECA integrates commonly used processes in the industry (Riveting, Vision, Datamatrix reading, RX Control, Robotics, Welding, Manufacturing, Micromechanics …).

We select universally recognized suppliers for serious process handling. Our goal is to ensure the reliability and performance of our machines throughout their programmed life.

CYBERMECA has ongoing cooperation with major industrial companies in demanding industries such as aeronautics, automobile, aerospace, armament or food-processing. This success is due to our multidisciplinary and versatile personnel.

Our work is strictly planned using the GPAO system, which enables us to trace our products from launch to delivery.

OUR KNOW-HOW

The differents steps of a project :

10 key points to success :

- Audit and consultancy

- Analysis – Consideration – Recommendation

- Requirements and specifications

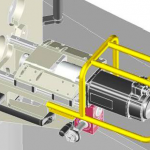

- Project development / CAD project design

- Work on machine (material / method integration)

- On-site integration

- Training

- Installation follow-up / Compliance with objectives

- On-site performance analysis

- Maintenance

Manufacturing process integration

Cybermeca is able to carry out a cutting-edge manufacturing process management through highly qualified and multidisciplinary technicians.

We have acquired a solid experience in robotics, vision, nondestructive testing, arc and laser welding, aircraft riveting, manufacturing, micromechanics, electrochermistry …

Our control engineers handle the integration of all technologies on our machines and manage HIM development tools, digital control and various programming methods.

Autonomy of our means

CYBERMECA’s autonomy is due to a careful management of all activities inside the group. We dispose of our own means : research, manufacturing, assembly, metal workshop, painting and control.